Why choose Sionics?

Our factory is designed to meet high standards of precision, speed and reliability, supporting everything from specialised prototyping to high-volume production. We continuously invest in the latest assembly technology to ensure your products are built to the highest standards.

- We cater for all types of PCB Assembly, Conventional (THT), SMT, Mixed or Flex.

- Full Turnkey Assembly - Component Sourcing / Procurement, Asssembly (SMT, THT, etc), Board Programming, Testing & Rework.

- Full box build services

- We can scale from orders of prototypes as little as 1 to hundreds or thousands of units (or many more). Our minimum order value is only £150.

- IPC Class 2 production as standard, ISO9001/2015 and ISO13485 Accredited.

- Same day courier delivery

Quality Management

All our production is assembled to IPC Class 2 as Standard. Additionally IPC Class 1 or 3 are available on request. Our processes are accredited to ISO 9001:2015 and ISO 13485, guaranteeing consistent quality and traceability across every project.

Our Services

PCB Assembly

With four modern production lines and a highly skilled team of engineers and operators, we handle everything from prototypes to volume manufacturing. Our expertise includes placing the latest component technologies, such as 01005 and micro BGAs, with precision and consistency.

Conformal Coating

Our new conformal coating system (Nordson ASYMTEK Select Coat SL-940) allows us to apply conformal coating with exceptional precision, protecting your PCBs against moisture, dust, chemicals, and extreme temperatures. Conformal Coating improves the durability of electronic components, and is ideal for assemblies that will be used in harsh environments like outdoors or automotive applications.

Cable Assembly

We provide tailored cable assembly services to meet your specific needs, from single prototypes to full-scale production. Whether you need custom wiring, cable prep, or wiring looms, we focus on delivering quality and flexibility. Many of our clients also integrate these assemblies with PCB-based orders, and we can ensure everything fits seamlessly into the final build. Get in touch to discuss your requirements.

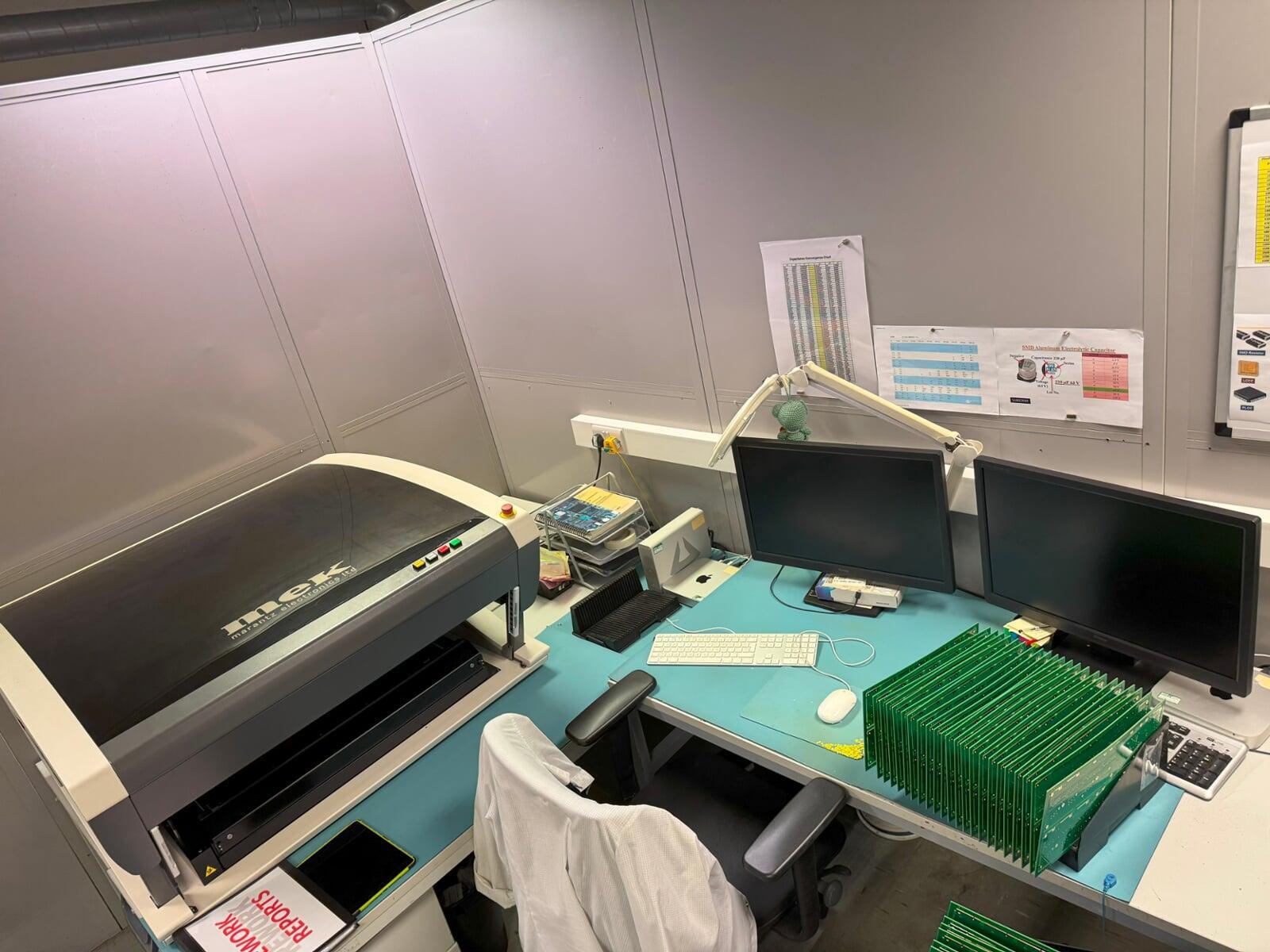

Inspection

We maintain the highest quality standards utilising both Automated Optical Inspection (AOI) and advanced X-Ray inspection. Our X-Ray system reveals hidden solder joints and internal connections, detecting issues like misalignment or bridging. This ensures the integrity of complex components such as BGAs and other critical parts, helping us catch any defects that aren’t visible externally.

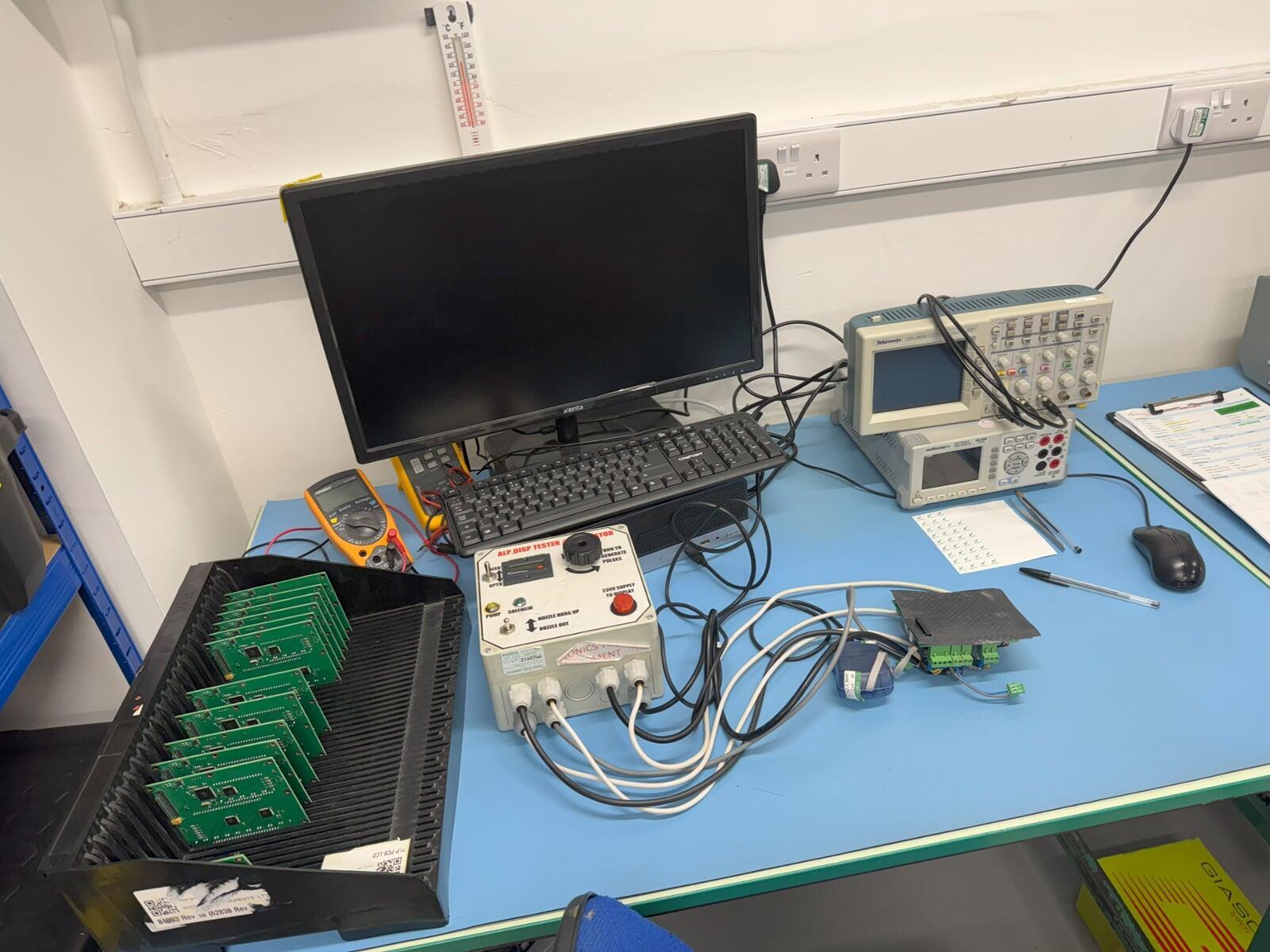

Testing

Alongside advanced AOI and X-ray inspection, we provide testing solutions to ensure every PCB assembly meets strict performance and quality standards. Our team can follow detailed manual test procedures, including board programming and functional testing. These capabilities help verify connectivity and end-to-end functionality—reducing defects and ensuring reliable performance in real-world applications.

Rework and Repair

We offer high-quality rework services using advanced rework stations and knowledge to meet the highest industry standards. Our skilled technicians will carefully remove, replace, or repair components on complex PCBs while minimising impact on surrounding areas. Whether for repairs, upgrades, or design changes, our rework and repair services are competitively priced for your requirements.

From Prototype To Production

At Sionics we can support you fully from concept to delivery. If your PCB layout or design needs adjustment we can help you make sure your designs work in real-world environments.

Our Production services include reviewing Gerber & PnP files to resolving track clearance issues, recommending better components & footprints and diagnosing issues.

Our background in prototyping and small-batch assembly within the UK gives us the speed and agility to support fast rapid development cycles, with the in-house capacity to scale with you through to full production volumes.

Quality Management

All our production is assembled to IPC Class 2 as Standard. Additionally IPC Class 1 or 3 are available on request. Our processes are accredited to ISO 9001:2015 and ISO 13485, guaranteeing consistent quality and traceability across every project.

Where it all began

About Us

We've continually invested in new technology to expand and improve our PCB assembly capabilities. As a result, we've grown significantly in recent years and now operate four SMT lines. Want to know more about how we got here? Visit our About Us page.

Make an enquiry

If you have any questions about our production capabilities or to make an enquiry, contact us and we will be happy to help. If you would like to pop in for a site visit or catch up, just let us know.